Stereolithography and Rapid Prototyping

First patented in 1983 by inventor Chuck Hull, stereolithography (SLA) is a three-dimensional printing technology that is used in producing models, prototypes and production parts. This technology has a variety of applications, including manufacturing, medicine, casting and architectural modeling. What differentiates stereolithography from other three-dimensionally printed media is the speed and level of detail offered. Starting with a CAD design, a model is built layer by layer in liquid resin that hardens when contacted by laser beam. This allows a designer to create a perfectly three-dimensional scale model without compromise or constraints encountered with milling machines or powder-based castings.

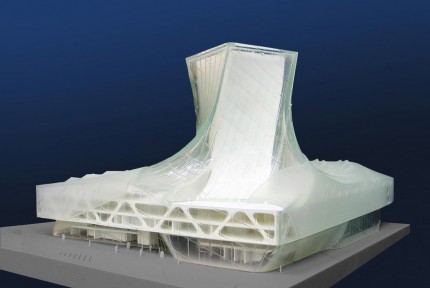

With technology like stereolithography, a designer may utilize rapid prototyping to further enhance or expedite the design process. An idea rendered in CAD may be quickly transferred into a scale model with reliable accuracy. This affords designers more time to resolve any spatial or architectonic problems. A terrain may be modeled in perfect detail, as seen in this scale model of downtown Chicago constructed with stereolithographic machines.

However, stereolithography is prohibitively expensive to use. Landscape architecture schools encourage familiarity with SLA technology and applications, but in the field it may not always be practical. With the $100,000 cost of an entry-level stereolithography machine, many firms still cannot see the full benefits of this technology. However, stereolithographic technology is quickly becoming more affordable, and small office-sized printers are now available.

Chicago Architecture Foundation

[…] article via Lab Visual Logic based on Chuck Hull’s invention of stereolithography – the earliest 3D printing process back in the early […]